High Pressure Underwater Inflatable Marine Lifting Airbag

Additional information

| Diameter | 0.8 ~ 2.5m, or customized diameter |

|---|---|

| Length | 5 ~ 25m, or customized length |

| Cord Layers Number | 4 ~ 12 Layers |

| Loading Capacity | 10 ~ 40 ton/m, or customized capacity |

| Certificate | Manufacturer Certificate, BV/ABS/LR/CCS Certificate |

| Model | QP-ordinary, QG-high-bearing, QS-superhigh bearing |

| Standard | ISO 14409 |

| Warranty | 24 Months |

High Pressure Underwater Inflatable Marine Lifting Airbag

High-pressure underwater inflatable marine lifting airbags are the toughest large pneumatic lifting bags for the huge structure, concrete caissons lifting and moving.

Air heavy lifting and transfer solutions are cost effective and flexible. This technique needs only compated ground and minimum facitlites that is specially suitable for temporary heavy lift and transfer projects.

Hight-pressure underwater marine lifting airbags are updated based on the ship launching airbags. This update makes heavy lifting marine airbags are more suitable for heavy lifting work. The highest lifting capacity of each heavy lifting airbag can reach about 300~500 tons. Another peerless character of our lifting bags is they can roller steadilly with the load. So our heavy lifting bags are especailly suitable for huge structure lifting and relocations.

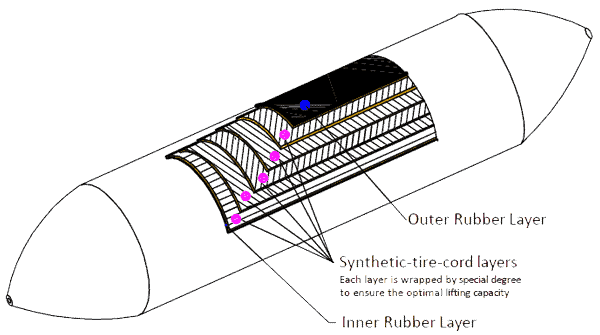

Construction of Underwater Inflatable Marine Lifting Airbags

High pressure marine lifting airbags are to be constructed of an out rubber layer, multilayer heavy-duty synthetic-tire-cord layers, and an inner rubber layer vulcanized firmly. Heavy lifting airbags are cylindrical balloon body, with two conical heads and two end mouths. Airtightness swivel and air inlet kits are screwed with end mouth.

-

Synthetic-tire-cord layer

The Synthetic-tire-cord layer is the reinforcement layer of the ship launching airbags which are made of rubber-coated synthetic-tire-cord fabrics. Many synthetic-tire cord layers are twined at ideal angles by unique and patented “Holistic Wrapping Technology“. To hold the internal pressure and to distribute the stress evenly. We use the 1870 dtex/2 type synthetic-tire-cord fabric. The warp is over 95 cords per 100 mm in width. The breaking strength is more than 310 N per cords.

-

Inner and Outer Rubber

Prior to the airbag production, the outer and inner rubber layers shall be tested to meet the criteria in accordance with the test methods given in the International Standards listed below. The outer rubber layer covers the outside of ship launching airbags. To protects the cord layers from abrasion and other external forces. This compound has sufficient tensile and tear strength to withstand any weather condition and hard usage.

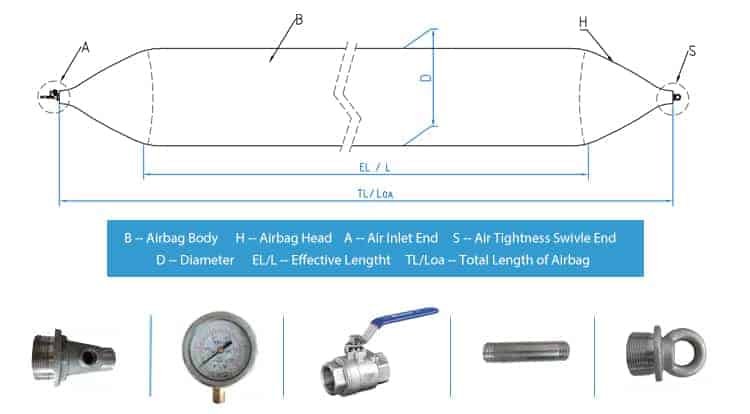

Structure of Underwater Inflatable Marine Lifting Airbags

The standard underwater marine lifting airbags include the below spares. Ready for use.

- The end of the airbag body

- End flange (Q235 H.D.G)

- Sealing Washer

- Three-direction connector at the inflate end (Q235 H.D.G)

- 3/4′ Ball Valves at the inflate end (Brass)

- Hose connection at the inflate end (Q235)

- High-quality Pressure Gauge

- 8. End plug at the tightness end (Q235 H.D.G)

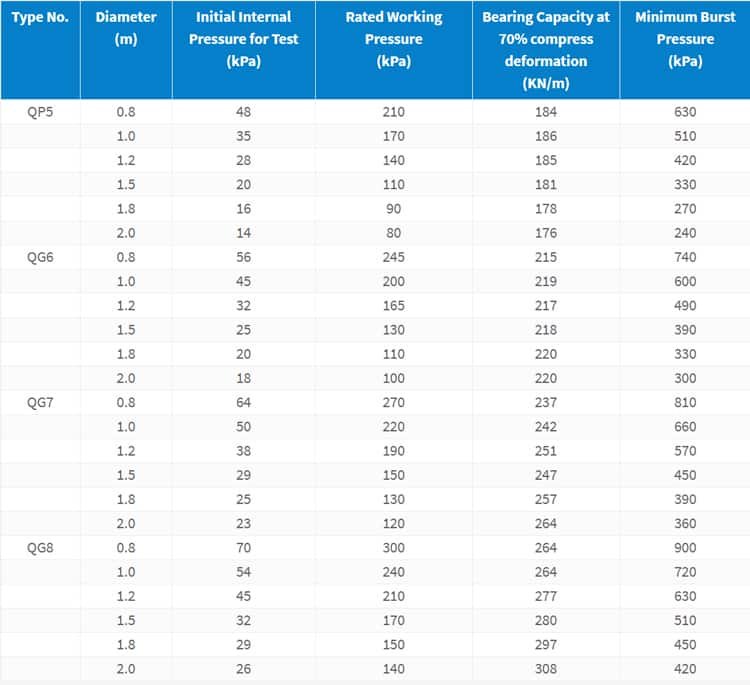

Classification of Underwater Inflatable Marine Lifting Airbags

High pressure underwater marine lifting airbags are categorized by the following three types according to the bearing capacity, per meter in length. We define the number of layers, which means the number of Synthetic-tyre-cord layers, in order to confirm the Safety Working Pressure. Another type is available upon clients’ request.

- QP – Ordinary airbag – with 3, 4 or 5 layers of cord fabric.

- QG – high-bearing capacity – with 6, 7, or 8 layers of cord fabric.

- QS – Superhigh-bearing capacity air bag – with 9, 10, or more layers of cord fabrics as custom request.

For example: QG6/1.5×15

QG6: 6 layers cord fabric

1.5: diameter is 1.5m

15: length is 15m

| Air Bag Parameter | Heavy Lifting Airbags Size |

|---|---|

| Product Name | Heavy Lifting Airbags |

| Diameter (D) | 0.8 ~ 2.5m, or customized diameter |

| Effective Length (EL) | 6 ~ 25m, or customized length |

| Total Length (TL) | 7 ~ 27m, or customized length |

| Loading Capacity | 10 ~ 40 ton/m, or customized capacity |

| Model of Airbags | QP-ordinary, QG-high-bearing, QS-superhigh bearing |

Inflatable Marine Lifting Airbags Features & Advantages

Doowin Marine heavy lifting airbags have different structures from the ship launching airbags. Not the simple other application of ship launching airbags. It can roll steadily when taking the load. The inferior lifting airbags are easy to twist.

Heavy-Duty, High Pressure — our heavy lifting airbags use the special synthetic-tire cord, which is stronger than the material used for the ship launching airbags. The highest working pressure can reach more than 400 kPa.

Super High Lifting Capacity — the maximum weight caissons move by heavy lifting airbags reach 5,000, cofferdams reach 2,200ton.

Cost-Effective, Flexible — the lifting and moving work using heavy lifting airbags doesn’t need the slipway, trolley. Low reaction force on the objects, safe for structure.

High Lifting Capacity

Air bags create high lifting capacity with safer low pressure. One air bag can lift 300~500 ton.

High Tensile Strength

Heavy-duty synthetic-tire-cord layers are the framework material. It can bear high working pressure.

Resistant to Abrasion

Rubber airbags have 6~12 plies reinforcement layers to withstand most abrasion and puncture.

Inflatalbe Underwater Marine Lifting Airbags Performance

Superior Manufacturing & Quality Control Processes from the selection of raw materials to the highly skilled production process

Underwater Marine Lifting Airbag Application

Heavy lifting and transportation relying on heavy lifting airbags are cost-effective and flexible. Doowin Marine heavy lifting airbags will provide you with a unique capability of land transport very large vessels, heavy loads, or heavy construction over the ground where the terrain would otherwise prevent such an operation.

The deflated heavy lifting airbag is very flat and can be placed under a grounded or stranded vessel that is hard aground. As little as 12 inches will provide a very quick placement of marine airbags under the hull.

The common mega structures has been successfully lifted and move by airbags incude concrete caissons, pumphouses, steel coeeerdams, bridge blocks and tanks. All of them have high sturcture strength and wide bottom. Alos there are some special objects has been relocated by airbags such as water diversion pipes and statues.

Caisson Liftingy

Used for caisson lifting and moving

Tank Lifting

Used for huge LPG, Oil Tank lifting

Culvert Lifting

Used for culvert lifting and moving

All Doowin Marine heavy lifting airbags are manufactured and insepcted fully compliant with ISO 14409 “Ships and marine technology – ship launching air bags“, certificated by CCS, LR, BV.

All Categories

Marine Rubber Airbags

FAQ

The weight of ship launching airbags is calculated by airbag surface area. When you care too much about weight, you may be misled by some manufacturers. Please remember “It’s not that the heavier the airbag, the better the quality. Weight is not a good indicator of quality.”

It is very easy to distinguish used and new airbags. If there are abrasions on the airbags body, then it is used one. For the new airbags, it’s surface maybe looks ugly and dirty. It is because we use French chalk in the vulcanization process. When the water vapor in the vulcanization tank is mixed with French chalk, the surface will appear very dirty.

Our unique overall winding technology is different from the current mainstream airbag production technology. We innovate and improve on the basis of mainstream production technology. The airbag produced by the optimal winding angle technology can exert the maximum effect of the material, save the cost, and have a stronger lifting force.

Marine rubber airbags are not single-use products. It can be used for many times. But cannot define the exact number. General speaking marine airbags have 5~8 years lifespan under the correct usage and proper maintenance.

Marine rubber airbags are not single-use products. It can be used for many times. But cannot define the exact number. General speaking marine airbags have 5~8 years lifespan under the correct usage and proper maintenance.

The ship launching airbags price is calculated by the airbag’s surface area, not weight. Rubber airbag has two cone shape ends. But we normally, make the airbags as cylindrical shape to calculate its surface area. Its calculate formal is S=π x Diameter x (Diameter+Effective Length) x layer numbers. Then, multiply the surface area by the unit price. The unit surface price is quite different for different factories, generally it is in the scope of USD4 to USD8 for each square meters.

CONTACT US TODAY

Our engineers are now available for a free consultation to help you find the right equipment for your project.