Pipeline Buoyancy Airbags Units

Additional information

| Diameter | 0.8 ~ 2.5m, or customized diameter |

|---|---|

| Length | 5 ~ 25m, or customized length |

| Cord Layers Number | 4 ~ 12 Layers |

| Loading Capacity | 10 ~ 40 ton/m, or customized capacity |

| Certificate | Manufacturer Certificate, BV/ABS/LR/CCS Certificate |

| Model | QP-ordinary, QG-high-bearing, QS-superhigh bearing |

| Standard | ISO 14409 |

| Warranty | 24 Months |

Pipeline Buoyancy Airbags Units

Pipeline laying buoyancy floatation is another application of ship launching marine airbags after update. Doowin Marine pipe laying buoyancy airbags are designed with lifting belts and shackles equipped on the updated ship launching airbags.

Pipe laying rubber airbags are the toughest air lifting bags. These rubber airbags can be installed on the pipeline by round sling. Its high working pressure can withstand water deepth up to 50m. It is very suitable for the pipeline surface pulling work and sink pipeline into seabed.

Why Rubber Pipe Laying Airbags

Rubber pipe laying airbags are made by multilayer heavy-duty synthetic-tire-cord layers. It’s more sturdy and reliability than PVC air lifting bags, what are widely used for the diving or marine salvage industry.

High Buoyancy

Rubber buoyancy airbags create high buoyancy capacity with safer air pressure. The buoyancy is 4t~300t.

Worked for Deep Water

Pipe laying rubber airbags can be used for deepwater salvage lifting. Can install safety valves.

Resistant to Abrasion

Pipe laying rubber air bags have 6~12 plies reinforcement layers to withstand most abrasion and puncture.

Structure of Pipe Laying Marine Rubber Airbags

Marine pipe laying rubber airbags are equipped with lifting belts and shackles. For the big size, we also install safety valves. When the inner pressure reaches the rated value, it can open automatically to release the insider air-pressure.

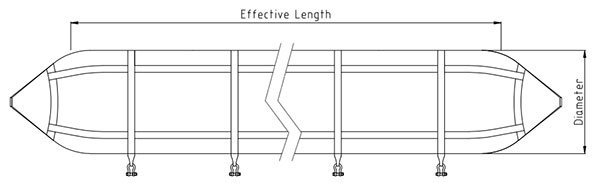

You can choose the required diameter and effective length to meet your projects. The below specification only is our standard specification arrangement. Other specifications marine salvage airbags also can be supplied upon clients’ request. The biggest buoyancy capacity can reach 300ton.

Air Bag Parameter | Marine Pipe Laying Buoyancy Rubber Airbags Size |

|---|---|

Product Name | Marine Pipe Laying Buoyancy Rubber Airbags |

Diameter (D) | 0.8 ~ 3m, or customized diameter |

Effective Length (EL) | 6 ~ 40m, or customized length |

Total Length (TL) | 7 ~ 45m, or customized length |

Loading Capacity | 4 ~ 300ton, or customized capacity |

Model of Airbags | QP-ordinary, QG-high-bearing, QS-superhigh bearing |

Pipe Laying Rubber Airbags Buoyancy Capacity

Marine pipe laying rubber airbags have different buoyancy capacities as well as performances With numerous combinations of diameters and lengths. Please refer below buoyancy list of standard pipe laying airbags.

Length | D=1m | D=1.2m | D=1.5m | D=1.8m | D=2.0m | D=2.5m | D=3.0m |

|---|---|---|---|---|---|---|---|

5m | 4t | 6t | 9t | 13t | 16t | 25t | 35t |

6m | 5t | 7t | 11t | 15t | 19t | 29t | 42t |

7m | 5t | 8t | 12t | 18t | 22t | 34t | 49t |

8m | 6t | 9t | 14t | 20t | 25t | 39t | 57t |

9m | 7t | 10t | 16t | 23t | 28t | 44t | 64t |

10m | 8t | 11t | 18t | 25t | 31t | 49t | 71t |

11m | 9t | 12t | 19t | 28t | 35t | 54t | 78t |

12m | 9t | 14t | 21t | 31t | 38t | 59t | 85t |

13m | 10t | 15t | 23t | 33t | 41t | 64t | 92t |

14m | 11t | 16t | 25t | 36t | 44t | 69t | 99t |

15m | 12t | 17t | 27t | 38t | 47t | 74t | 106t |

16m | 13t | 18t | 28t | 41t | 50t | 79t | 113t |

17m | 13t | 19t | 30t | 43t | 53t | 83t | 120t |

18m | 14t | 20t | 32t | 46t | 47t | 88t | 127t |

19m | 15t | 21t | 34t | 48t | 60t | 93t | 134t |

20m | 16t | 23t | 35t | 51t | 63t | 98t | 141t |

21m | 16t | 24t | 37t | 53t | 66t | 103t | 148t |

22m | 17t | 25t | 39t | 56t | 69t | 108t | 156t |

23m | 18t | 26t | 41t | 59t | 72t | 113t | 163t |

24m | 19t | 27t | 42t | 61t | 75t | 118t | 170t |

25m | 20t | 28t | 44t | 64t | 79t | 123t | 177t |

Marine Rubber Airbags Various Application

Rubber marine airbags have various application. It can be used for marine salvage or re-floatation objects from the seabed. It also can be used for buoyancy support, marine salvage, and re-floatation operation. Furthermore, we also can use marine salvage rubber airbags as buoyancy support pontoons for bridges, floating platforms, dock gates, sunken objects, or military equipment. Marine salvage airbags offer an effectual floatation method of reducing the draught of the vessel and lift bag salvage underwater structures.

Refloat Sunken Ships

Shipwreck salvage and floatation

Buoyancy Compensation

Provide buoyancy for ship

Pipeline Buoyancy Support

Used for pipeline floating

All Doowin Marine pipe laying rubber airbags are manufactured and insepcted fully compliant with ISO 14409 “Ships and marine technology – ship launching air bags“ and IMCA D016, certificated by CCS, LR, BV.

Single point buoyancy units are one-kind enclosed pipeline buoyancy bags. It only has one single lifting point. So it is very effective for the steel or HDPE pipelines laying work at or near the surface. Moreover, it also can work at a large angle, like the parachute type air lift bags. Vertical single-point buoyancy units are made of heavy-duty PVC coating fabric material that complies with IMCA D-016.

All Categories

Marine Rubber Airbags

FAQ

The weight of ship launching airbags is calculated by airbag surface area. When you care too much about weight, you may be misled by some manufacturers. Please remember “It’s not that the heavier the airbag, the better the quality. Weight is not a good indicator of quality.”

It is very easy to distinguish used and new airbags. If there are abrasions on the airbags body, then it is used one. For the new airbags, it’s surface maybe looks ugly and dirty. It is because we use French chalk in the vulcanization process. When the water vapor in the vulcanization tank is mixed with French chalk, the surface will appear very dirty.

Our unique overall winding technology is different from the current mainstream airbag production technology. We innovate and improve on the basis of mainstream production technology. The airbag produced by the optimal winding angle technology can exert the maximum effect of the material, save the cost, and have a stronger lifting force.

Marine rubber airbags are not single-use products. It can be used for many times. But cannot define the exact number. General speaking marine airbags have 5~8 years lifespan under the correct usage and proper maintenance.

Marine rubber airbags are not single-use products. It can be used for many times. But cannot define the exact number. General speaking marine airbags have 5~8 years lifespan under the correct usage and proper maintenance.

The ship launching airbags price is calculated by the airbag’s surface area, not weight. Rubber airbag has two cone shape ends. But we normally, make the airbags as cylindrical shape to calculate its surface area. Its calculate formal is S=π x Diameter x (Diameter+Effective Length) x layer numbers. Then, multiply the surface area by the unit price. The unit surface price is quite different for different factories, generally it is in the scope of USD4 to USD8 for each square meters.

CONTACT US TODAY

Our engineers are now available for a free consultation to help you find the right equipment for your project.