Offshore Mooring Buoys

Offshore Mooring Buoys

Offshore mooring buoys are in service for inland waterways and offshore instead of traditional steel mooring buoys.

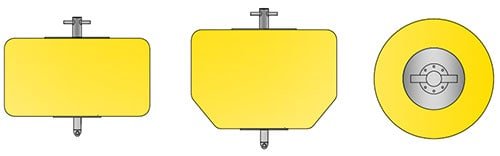

The cylindrical offshore mooring buoy is one kind of representative mooring buoys. The cylindrical mooring buoys can be supplied in chain-through type, or equipped with pad-eye, crucifix, quick release hook, and maker or navigation equipment. Other variety end fittings are available to suit every case application. All end fittings are made of galvanized or painted steel to resist seawater corrosion.

Offshore Mooring Buoys Specification

The below table shows the most commonly requested size only. The standard color is yellow and orange.

Type | Length (mm) | Overall Length (mm) | Diameter (mm) | Weight (kg) | Net Buoyancy (kg) | Net Buoayncy (lbs) |

|---|---|---|---|---|---|---|

CMB1 | 700 | 1500 | 1500 | 161 | 1000 | 2207 |

CMB3 | 1100 | 2000 | 2200 | 544 | 3000 | 6620 |

CMB5 | 1500 | 2500 | 2500 | 1104 | 5000 | 11033 |

CMB8 | 1500 | 2500 | 3100 | 1698 | 8000 | 17652 |

CMB10 | 1500 | 2500 | 3300 | 1924 | 10000 | 22065 |

CMB15 | 2000 | 3000 | 3500 | 2886 | 15000 | 33098 |

CMB20 | 2000 | 3000 | 4000 | 4021 | 20000 | 44131 |

CMB25 | 2000 | 3000 | 4000 | 5027 | 25000 | 55163 |

CMB30 | 3000 | 4000 | 4200 | 6650 | 3000 | 66196 |

Offshore Mooring Buoys Features

Offshore mooring buoys have significant advantages, lier easier to handle, better corrosion resistance, low maintenance, never sink or burst, self-fendering that withstands vessel impact.

- PU Protective Outer Skin – Reinforced urethane elastomer skin

- Self-fendering – High impact absorption capacity

- Inner Foam – Unskinable closed-cell rigid foam core

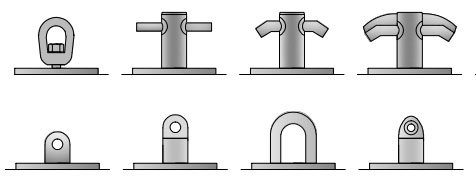

- Upper-End Fitting – Various end fitting options available

- Internal Steel Core – For better support and balance

- Lower End Fitting – Mooring eye used for anchor connecting

Construction of Offshore Mooring Buoys

The offshore mooring buoys are manufactured with high-quality closed-cell PE/EVA resilient foam, encapsulated with self-colored tough polyurethane elastomer skin.

- Tough reinforce polyurethane outer skin – General surface support buoy’s skin is constructed of polyurethane elastomer, which also can be reinforced with nylon filament. The polyurethane skin is a unique elastomer specifically for offshore applications. It is high resistance to abrasion, fatigue, and ultraviolet degradation and is significantly more durable.

- Laminated closed cell resilient foam core, unsinkable design – General surface support buoys are made with the highest quality closed-cell PE/EVA foam. This resilient foam makes the buoys self-fendering with high impact absorption capacity. Even the skin was punctured, it also is unsinkable without absorbing water. With our unique laminating process, each foam core is integrity. The foam core cannot be reputed after a long time of service.

- Steelwork and end assembly – Through central steel tube with longitudinal gussets and external load distribution flanges at each end, epoxy coated or hot-dipped galvanized, are encased in a closed-cell urethane foam central body. Optional bail eye, clevis eye, swivel, chain locking plate, single locking pin end fitting are available.

All Categories

General Surface Buoys

Related products

CONTACT US TODAY

Our engineers are now available for a free consultation to help you find the right equipment for your project.