ROV Buoyancy Modules

Additional information

| Material | Chemical Foam, Syntactic Foam |

|---|---|

| Density | 0.08 ~ 0.2 g//cm3, 0.35~0.7 g/cm3 |

| Water Depth | 50 ~ 11,000m |

| Compression Strength | 2~5.19 Mpa, 8~90 Mpa |

| Water Absorption | < 2% |

| Usage | Subsea Buoys and Buoyancy Modules |

| Appearance color | Orange, Yellow, Red and others |

ROV Buoyancy Modules

The subsea solid buoyancy material is a solid compound obtained by filling an organic polymer material with an inorganic light-weight filler material through a physical and chemical reaction. The deep-sea buoyancy material is a low-density, high-strength porous structure material. It is a counterweight material for underwater operation equipment.

The subsea buoyancy module is a polymer-based solid material with low density, high strength, and low water absorption. It has the characteristics of low density (0.35~0.7g/cm3), low water absorption ( ≤2%), high mechanical strength (compressive strength 1~100MPa), corrosion resistance, and secondary mechanical processing.

The solid buoyancy modules can meet the requirements of different underwater applications. An underwater system made of high-performance solid buoyancy materials. Not only can it dive to greater depths, increase the payload, and reduce energy consumption. And it can maintain a stable working condition underwater. Deep-sea solid buoyancy materials are an indispensable part of deep diving technology in the 21st century.

Chemical Foaming Solid Buoyancy Material

The chemical foaming method buoyancy material is a kind of polyurethane-epoxy resin rigid foam composite material made by the chemical foaming method.

Model | Density (g/cm3) | Compression Strength (MPA) | Water Absorption (24H) | Submersible Depth (m) |

|---|---|---|---|---|

CSBM-08 | 0.08 | / | ≤2% | 50 |

CSBM-15 | 0.15 | 2.6 | ≤2% | 100 |

CSBM-20 | 0.20 | 5.19 | ≤2% | 200 |

Syntactic Foam

Syntactic foams are composite materials synthesized by filling a metal, polymer, or ceramic matrix with hollow spheres called micro balloons or cenospheres or non-hollow spheres.

Model | Density (g/cm3) | Compression Strength (MPA) | Water Absorption (24H) | Submersible Depth (m) |

|---|---|---|---|---|

SBM-35 | 0.35±0.02 | ≥8 | ≤2% | 200 |

SBM-37H | 0.37±0.02 | ≥12 | ≤1% | 500 |

SBM-38 | 0.38±0.02 | ≥10 | ≤1% | 300 |

SBM-40 | 0.40±0.02 | ≥12 | ≤1% | 500 |

SBM-40H | 0.40±0.02 | ≥18 | ≤1% | 1000 |

SBM-45 | 0.45±0.02 | ≥20 | ≤1% | 1000 |

SBM-48 | 0.48±0.02 | ≥25 | ≤1% | 2000 |

SBM-51 | 0.51±0.02 | ≥35 | ≤1% | 3000 |

SBM-54 | 0.54±0.02 | ≥45 | ≤1% | 4500 |

SBM-57H | 0.57±0.02 | ≥55 | ≤1% | 6000 |

SBM-63 | 0.63±0.02 | ≥55 | ≤1% | 6000 |

SBM-70 | <0.7 | ≥90 | ≤1% | 11000 |

Subsea Buoyancy Modules Products

The subsea buoyancy material is mainly used underwater. Based on its characteristics of low density and high-pressure resistance, it mainly provides the required buoyancy for underwater operation equipment. Spray coating or protective layer treatment can be applied to the surface as required. Often manufactured and processed into floats, buoys and other counterweight products. It can also be directly machined into product parts.

It can not only meet the mechanical requirements of the product structure, but also greatly reduce the product weight and other functions. The application of this material realizes the functions that are difficult for metal structural parts to realize. At present, it has been used in underwater deep submersibles, underwater robots, etc., and can be used safely at depths of several thousand meters underwater.

ROV/AUV Buoyancy Modules

Ocean Equipment Buoyancy Modules

Customized Buoyancy Modules

Cable Umbilical Floats

Subsea Buoyancy Blocks

Subsea Spherical Buoys

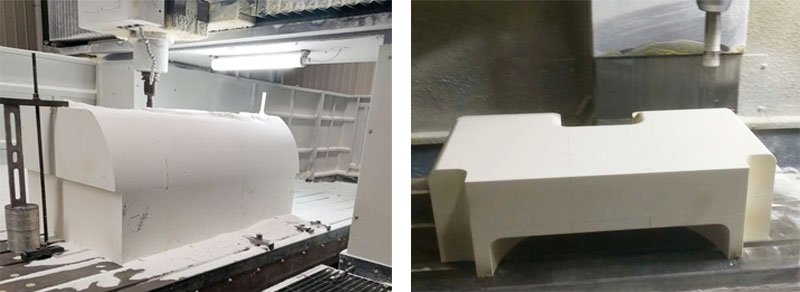

Syntactic Foam CNC Production

All Categories

Subsea Buoyancy Foam

Related products

CONTACT US TODAY

Our engineers are now available for a free consultation to help you find the right equipment for your project.