Netted Foam Filled Fender

Additional information

| Diameter | 0.5m ~ 4.5m |

|---|---|

| Length | 1.0m ~ 9m |

| Parts | Chain and Tire Net, Flange |

| Standard | ISO 17357 |

| Initial Pressure | 50kPa & 80kPa |

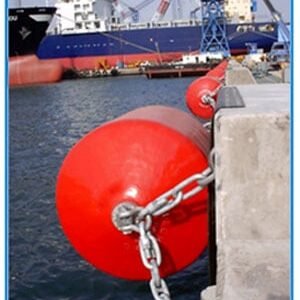

| Usage | Ship and Port Protection |

| Origin | Qingdao, China |

| Payment Term | L/C, D/A, D/P, T/T, Western Union |

| Warranty | 24 Months |

Netted Foam Filled Fender

Foam fenders is one kind tough heavy-duty and unsinkable floating fender system. They are often used for harbor, offshore, and ship-to-ship applications. Foam-filled fenders have higher energy absorption with lower reaction force. Its performance is higher than the pneumatic rubber fenders and other marine fenders. Its self-floating characteristic ensures foam fenders are workable for ship-to-ship operation.

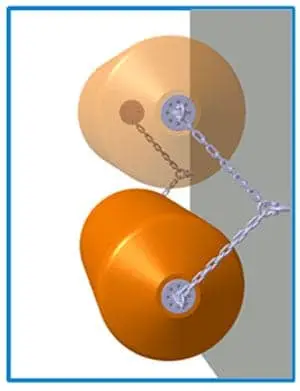

- Netless foam fenders are without the chain and tire net

- Netted foam fenders are with the chain and tire net protection.

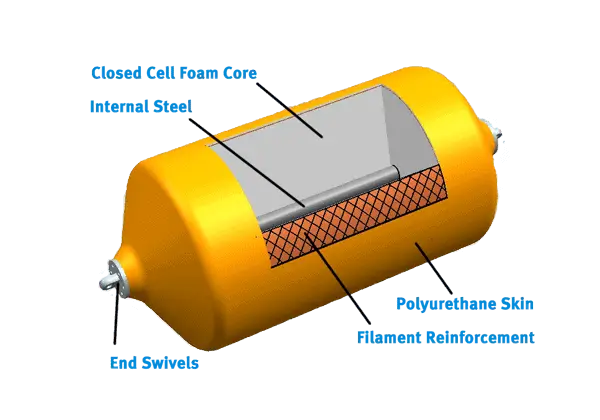

Foam Fenders Construction

Foam fenders are constructed of three parts providing an important function in the construction. The outside closed-cell polyethylene foam core absorbs the impact from severe operating conditions, while the inside skin of reinforced polyuretane elastomer resists wear and tear among austere condition.

High Performance Unskinable Closed Cell Foam

Foam filled fenders are filled with highest quality 100% closed-cell foam. This specific foam can provide high energy absorption with relatively low reaction force. Even the skin was punctured, it also is unsinkable without absorbing water. With our unique laminating process, each foam core is integrity. The foam filled fenders core cannot be ruptured when compressed.

Strong and Tough Skin for Foam Fenders

Netless foam filled fenders skin is constructed of polyurethane elastomer. The polyurethane skin is unique elastomer specifically for fender applications. More thick filaments and elastomer are applied to both ends to better resist the defection and shearing force.

High Quality Steel Structure Support Foam Fenders

Comprising through central steel tube and external load distribution flanges at each end. Heavy duty internal chain connecting the end fitting through central tube is applied to transmit tensile load through the fender. All end fitting of foam filled fenders are hot-dip-galvanized.

Foam Filled Fenders Features

Foam Filled Fenders are versatile, robust, and suitable for almost all applications. Foam-filled fenders are constructed with closed-cell, energy absorbing resilient foam laminated layers, and tough polyurethane skin. This construction offers several important features and advantages.

- High energy absorption and low reaction force

- Ultr-tough polyurehane skin

- Unsinkable design even if skin is punctured

- Easy instllation and Low Maintenance

- Customized size and in various colors

Foam Fenders Specification

Fender Size Fender Size | Fender Size D x L (ft) | Energy Absorption kNm | Reaction Force (KN) |

|---|---|---|---|

700 x 1500 | 2.3 x 4.9 | 26 | 133 |

1000 x 1500 | 3.3 x 4.9 | 47 | 173 |

1000 x 2000 | 3.3 x 6.5 | 68 | 254 |

1200 x 2000 | 3.9 x 6.5 | 91 | 280 |

1350 x 2500 | 4.4 x 8.2 | 152 | 418 |

1500 x 3000 | 4.9 x 9.8 | 244 | 596 |

1700 x 3000 | 5.6 x 9.8 | 282 | 618 |

2000 x 3500 | 6.5 x 11.5 | 454 | 845 |

2000 x 4000 | 6.5 x 13.1 | 540 | 1005 |

2000 x 4500 | 6.5 x 14.7 | 624 | 1161 |

2200 x 4000 | 7.2 x 13.1 | 541 | 915 |

2200 x 5500 | 7.2 x 16.4 | 847 | 1437 |

3000 x 6000 | 9.8 x 19.7 | 1914 | 2336 |

3300 x 4500 | 10.8 x 14.7 | 1498 | 1690 |

3300 x 6500 | 10.8 x 21.4 | 2421 | 2731 |

All Categories

Foam Filled Fenders

CONTACT US TODAY

Our engineers are now available for a free consultation to help you find the right equipment for your project.